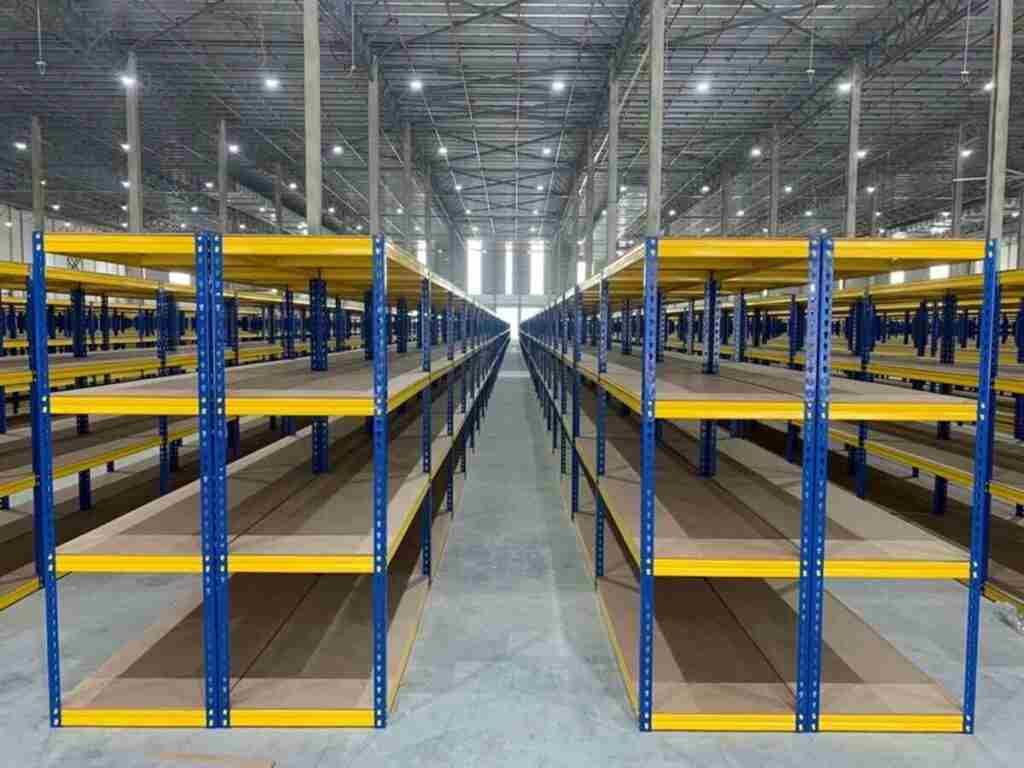

The Ultimate Guide to DIY Boltless Racking System

Regarding efficient, sturdy, and easy-to-install storage solutions, DIY boltless racking systems have emerged as a top choice for homes, offices, and warehouses. Known for their flexibility, boltless racks provide a durable, customizable option that can easily accommodate a range of storage needs without the hassle of screws or bolts. This guide will delve into everything you need to know about DIY boltless racking systems, from their key benefits to step-by-step installation tips. Let’s get organized with this effective storage solution!

What is a Boltless Racking System?

A boltless racking system is a type of shelving unit that doesn’t require bolts, nuts, or screws for assembly. Instead, it uses a rivet-and-slot design, allowing for a quick and easy setup. With simple assembly and versatility, boltless racks are a practical solution for anyone seeking efficient storage. The racks can be adjusted to various configurations, and each shelf level is typically reinforced with metal or particle board, enabling them to hold substantial weights.

Benefits of a DIY Boltless Racking System

1. Ease of Assembly

Boltless racking systems are designed for quick assembly. The lack of bolts and screws means that installation is a straightforward task, saving time and effort. With just a rubber mallet, most individuals can put the rack together in minutes, making it ideal for beginners and seasoned DIYers.

2. High Load-Bearing Capacity

These racks are incredibly sturdy and designed to bear heavy loads, making them suitable for various storage applications. Depending on the design, boltless racks support weights ranging from 200 kg to over 500 kg per shelf, whether storing tools, office supplies, or household items.

3. Cost-Effective Storage Solution

Unlike other shelving units, boltless racks offer a cost-effective option without sacrificing quality. The simple design reduces manufacturing costs, allowing consumers to access reliable storage solutions at an affordable price.

4. Customizable and Adjustable

A major advantage of DIY boltless racks is their flexibility. The shelves can be easily adjusted to different heights, allowing users to customize the unit based on their specific storage requirements. This feature is especially useful for accommodating items of varying sizes.

5. Durable and Long-Lasting

Made from high-quality steel or metal, boltless racks are built to withstand regular use. Their durable construction ensures that the racks remain stable and functional for years, even when supporting heavy items.

Essential Tools and Materials for DIY Boltless Rack Installation

Before starting the installation, gather the following tools and materials:

- Rubber Mallet: Essential for securing the pieces in place without damaging the metal.

- Level: Helps ensure that the shelves are perfectly horizontal, preventing instability.

- Gloves: Protect your hands during the assembly process.

- Racking Kit: This will include uprights, beams, and shelf boards (typically metal or particle boards).

Having these tools and materials ready will make the installation smoother and quicker.

Step-by-Step Guide to DIY Boltless Rack Installation

Step 1: Prepare the Area

Clear out the space where you plan to install the rack. Ensure the floor is level and clean to provide a stable foundation. If setting up in a garage or warehouse, ensure ample room to manoeuvre the rack components.

Step 2: Organize the Parts

Unbox the racking kit and organize all parts, including the uprights, beams, and shelf boards. Confirm that you have all necessary components before starting the assembly to avoid disruptions.

Step 3: Start with the Bottom Shelf

Begin by placing the bottom horizontal beams on the ground and attach them to the vertical uprights. Use a rubber mallet to tap each connection gently until secure. Starting with the bottom shelf ensures a strong base and makes it easier to add additional shelves as you move up.

Step 4: Add the Remaining Shelves

Once the bottom shelf is stable, continue to add the remaining shelves, working upward. Place the beams in the desired slots for each level and secure them with the mallet. Adjust the height of each shelf according to your storage needs, as boltless racks allow for customization at each level.

Step 5: Insert the Shelf Boards

After installing all levels, place the shelf boards onto the beams. Double-check that each shelf is level and securely positioned on the beams. This step adds stability to the structure, ensuring the racks can hold weight safely.

Step 6: Final Adjustments and Inspection

Once assembled, give the rack a final inspection. Check that each beam is securely attached and that there’s no wobbling. If necessary, adjust any beams or shelves to ensure stability and evenness.

Top Tips for Maintaining Your Boltless Racking System

- Avoid Overloading: Follow the manufacturer’s guidelines on weight capacity to prevent structural damage.

- Regular Cleaning: Dust and debris can accumulate on the shelves, so they should be cleaned regularly to keep them in good condition.

- Inspect for Stability: Periodically check for any loose components and make adjustments if needed.

- Use in a Dry Environment: To prevent warping, use particle board shelves that are kept away from moisture.

- Reorganize When Necessary: Use the adjustable shelves to optimize space as storage needs change.

FAQs about DIY Boltless Racking System

1. How much weight can a DIY boltless racking system support?

Boltless racking systems can support a substantial amount of weight, often ranging from 200 kg to over 500 kg per shelf, depending on the model and materials used. To maintain stability and longevity, be sure to check the specifications of your particular model and avoid exceeding the recommended weight limit.

2. Can boltless racks be used for industrial purposes?

Yes, boltless racks are widely used in warehouses, garages, and other industrial settings. Their high load capacity and sturdy design make them ideal for heavy-duty applications. They’re particularly useful in environments where efficient and adaptable storage solutions are needed.

3. Are boltless racks easy to disassemble and reassemble?

One of the primary benefits of boltless racking systems is their ease of assembly and disassembly. They can be taken apart and reassembled quickly, making them ideal for spaces that require frequent reconfiguration or for those who may need to relocate the shelving system.

4. Can I adjust the height of the shelves after assembly?

Yes, the shelves on boltless racks are adjustable. If you need to rearrange the shelf height after initial setup, you can easily remove and reposition them without requiring tools or extra components.

5. Are there specific precautions to take when installing a boltless racking system?

When installing a boltless rack, always ensure that the floor is level and that each component is securely tapped into place. Avoid placing the heaviest items on top shelves to maintain stability, and regularly inspect the unit for any loose components to prevent accidents.

Conclusion

DIY boltless racking systems offer a versatile, cost-effective, and durable storage solution that fits seamlessly into various environments, from homes and offices to warehouses and retail spaces. Their ease of assembly, high load capacity, and customizable shelving make them an excellent choice for those looking to optimize storage efficiently. By following the step-by-step installation guide and keeping up with regular maintenance, you can ensure your boltless rack remains functional and safe for years.

Want to learn more about boltless racks? Read: https://alzaibcity.com/why-the-4-level-boltless-rack-is-so-popular-in-malaysia/